08

March

2023

Interactive Wear wins the QRDI's qatar open innovation award for Smart PPE

Interactive Wear wins the QRDI's Qatar Open Innovation Award for "Smart Personal Protective Equipmen (PPE) for Worker's Health, Safety and Security"

The goal of the Work Trial is to generate data with and without active cooling solutions. These data will be enriched by data from occupational health reports and analysed with neural networks. The expected outcome are validated algorithms for an embedded Thermal Monitoring System that could be used for an alert system as well as for health documentation and objective insight about the health and performance effect of active cooling solutions and proposals for the most effective and efficient active cooling components. The thermal monitoring system will include climate and temperature sensors, enhanced with other sensors (e.g., activity sensor, respiration sensor, smart watch integration).

23

february

2023

Ergonomic assistance systems for grid control centers in critical infrastructures

Project Kickoff BEAUTIFUL, Aachen, 23./24.02.2023

The increasing technological and systemic complexity of energy systems and the increased risk of cyberattacks lead to a significant increase in relevant process information that needs to be considered by the control center operators. The BMBF-funded BEAUTIFUL project aims to optimise the working conditions of the operators in critical infrastructures by developing innovative assistance systems to support fast and safe decisions in complex situations.

Interactive Wear will implement distributed wearable sensors and sensor fusion algorithms to measure physiological data of the operators to determine the stress level and mental fatigue.

20

january

2022

Interactive Wear adds NFMI communication to its technology portfolio

Adding NFMI (near field magnetic induction) technology enables Interactive Wear to support customers in new areas of BSN (Body Sensor Networks) and IoT applications, where conventional RF technologies have their limitations.

In the recently completed BIONIC project for posture and fatigue analysis in industrial and construction work environment, Interactive Wear realized a near field magnetic induction (NFMI) communication node to connect a head-worn sensor with a textile wired BSN. NFMI was chosen to provide stable, private and low energy communication in industrial and construction environments. The systems were successfully tested at Rolls Royce Power Systems in Friedrichshafen, Germany.

NFMI is well suited for low power wireless communication where Bluetooth has its limitations, especially for communication through the body, in shoe-soles or under water.

The NFMI technology has several benefits compared to conventional RF technology.

- It does not interfere with Bluetooth and Wi-Fi

- It is private because of the very limited range of transmission

- It works under water, as water does not absorb the magnetic field

- It is power efficient as NFMI devices last up to five times longer than comparable Bluetooth devices

- It is multi-point and real-time capable, designed to connect many devices

Interactive Wear’s BSN is a modular wired/wireless multi-sensor system that enables a wide range of applications through sensor fusion using motion analysis, climate and vital parameters. The system can integrate sensor data from smart phones and smart watches, as well as customized third-party sensor data. New insights can be generated through neural network capabilities, e.g., detecting new patterns and events for monitoring applications. Communication via textile cable and wireless via Bluetooth LE has been extended by an additional technology NFMI.

Customers can be supported in developing NFMI applications via prototyping workshops, feasibility studies, and custom specific development projects.

28

oktober

2021

Invisible Motion Tracking at Work – BIONIC Pilots Started

Sensor technology and AI for smart workwear to provide healthy and secure work conditions

Two pilots have been launched in the BIONIC research project. After a preliminary trial in July, the motion tracking systems are being put into test mode at Rolls Royce Power Systems in Friedrichshafen in October 2021. Last week, they have also been introduced at construction sites of Acciona in Spain. AI is used to evaluate the collected data in real time to facilitate detection of poor posture while working. Countermeasures can thus be taken at an early stage.

BIONIC stands for personalized body sensor networks with built-in intelligence for real-time risk assessment and coaching of workers, in all types of working and living environments. BIONIC systems are inconspicuously integrated into the usual work clothing and can monitor movements at the workplace during an entire shift. In case of unfavorable or health-endangering movements, the worker receives feedback. The systems can also be used during training and exercises.

Interactive Wear led the development of a modular and scalable sensor network to acquire and synchronize sensor data from distributed wearable sensors. Lightweight and robust textile cable were used for interconnection and invisible integration into work wear. Additionally, Interactive Wear has developed several economic variants with 2-4 sensors suitable for daily monitoring with a different application focus.

The concept of distributed sensor systems has already been successfully implemented in several projects. The UK based company Feraru Dynamics, for example, integrated a vibration-sensing system into a glove. This enables employees, who are exposed to (mechanical) vibration, to protect from such injuries as hand-arm vibration syndrome (HAVS).

The systems can be used in multiple ways:

- For recording, analysis, and optimization of movements at a specific workplace. In this case, the systems consist of several motion and physiological sensors, usually 6-12, integrated in the typical work clothing.

- These systems could be also used for training programs with specific exercises.

- As a monitoring device for workers at the workplace, to measure the load over time from certain motions with high stress impact. For this purpose, systems with usually 2-4 sensors, are used.

Project Kickoff EGHI

“Adaptive technologies for society – Intelligent interaction between humans and artificial intelligence”

- A project within the framework of the “Adaptive Technologies for society – Intelligent interaction between humans and artificial intelligence” programme, sponsored by the German Federal Ministry of Education and Research

- EGHI – stands for enhanced (good) health intelligence for personal behavioural strategies in everyday life

- Interactive Wear is taking part in the EGHI research project to combine sensor data from smartphones and smartwatches with wearable sensors / smart textiles, with the aim of enabling open, individualised solutions.

09

February

2021

Intelligent optimisation of artificial intelligence

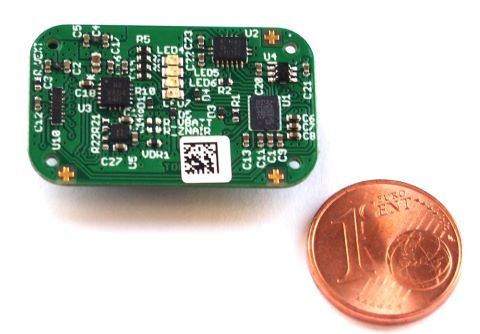

As part of the i-compression research project, the Nursing Research Group of the Geriatrics Research Group at the Charité Universitätsmedizin Berlin has been using Interactive Wear’s MicroHub development system to record motion data, which were then classified by Interactive Wear. The motion patterns that needed to be detected were lying, sitting, standing, walking and climbing stairs, as well as two exercises typically used for mobilisation.

By using neural networks – convolutional neural networks with 3-5 levels implemented in Python/PyTorch – a hit rate of 85% to 93.2% was achieved. The same neural networks with Interactive Wear's Enhanced Features, on the other hand, yielded hit rates of over 99.5%. Since these hit rates can be achieved even with single-layer networks, the resource requirement for computation is also significantly reduced. A network created in this way can then run on a small, low-power ARM M0+ class microcontroller, in real time, with analyses performed every 2-3 seconds.

About sensor application development at Interactive Wear:

The Interactive Wear tools include hardware and software development systems that are suitable for a wide spectrum of body sensor network applications. The development systems and methods enable rapid prototyping of customer applications. The spectrum ranges from simple applications with 6 or 9-axis IMUs (inertial measurement units) to distributed systems with multiple IMUs and analogue sensors (e.g. pressure, strain) for sensor fusion as well as the integration of actuators. Data acquisition during the development phase is performed using a data logger that is adapted to the respective application and supports both live observations and analysis of recorded sensor data.

If you have any questions, please contact us at

i-compression is funded by the Federal Ministry of Education and Research (BMBF) over three years as part of the KMU-innovativ funding initiative for SMEs